The History of Jingdezhen Ceramics

Located in China's Jiangxi Province, Jingdezhen boasts a history of porcelain making that spans over 1,700 years.

Jingdezhen's porcelain journey began during the Han Dynasty (202 BC - 220 AD), when locals began crafting simple pottery. Over time, by the Tang Dynasty (618 - 907 AD), Jingdezhen had become renowned for producing high-quality celadon (blue-colored porcelain) and white porcelain. These porcelains, famous for their delicate texture and smooth glaze, began to be traded throughout China.

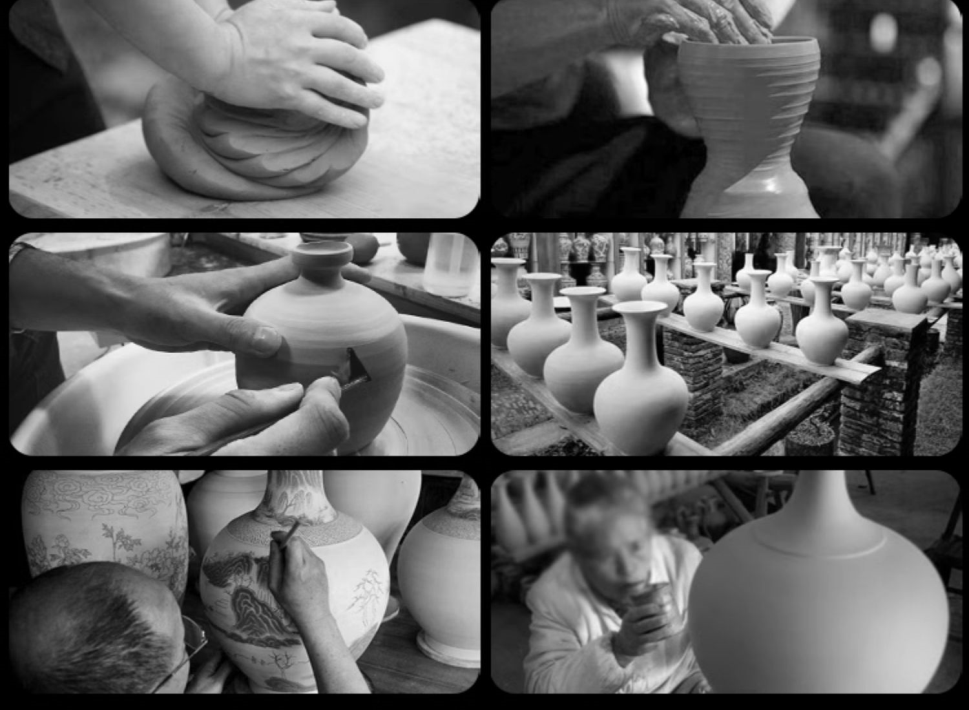

Basic Ceramic Production Process

1. Select and prepare the ceramic raw materials.

2. Form the body.

3. Allow to air dry.

4. Glaze to impart color and luster to the ceramic.

5. Firing at high temperatures. This is the transformation from clay to ceramic.

6. Apply decorations such as painting and carving, and polish to enhance the texture.

Image with text

Today, Jingdezhen still preserves its traditional techniques for making porcelain. It remains a major porcelain production center in China, attracting porcelain enthusiasts, artists, and collectors from around the world. Jingdezhen's porcelain showcases a long history of porcelain-making and constantly innovative craftsmanship, becoming a living museum of Chinese porcelain culture.